Understanding the Lifespan of Rotary Switch 3 Position Components: A Comprehensive Guide

Sep 11,2025

Understanding the Lifespan of Rotary Switch 3 Position Components

Rotary switches play a pivotal role in various electronic devices, enabling users to control multiple circuits with ease. Among the various types of rotary switches, the 3 position components stand out for their versatility and efficiency. In this article, we will explore the lifespan of rotary switch 3 position components, factors

Understanding the Lifespan of Rotary Switch 3 Position Components

Rotary switches play a pivotal role in various electronic devices, enabling users to control multiple circuits with ease. Among the various types of rotary switches, the 3 position components stand out for their versatility and efficiency. In this article, we will explore the lifespan of rotary switch 3 position components, factors affecting their longevity, maintenance practices, and more.

Table of Contents

- What are Rotary Switch 3 Position Components?

- How Rotary Switches Work

- Factors Affecting the Lifespan of Rotary Switch 3 Position Components

- Typical Lifespan of Rotary Switch Components

- Best Practices for Maintaining Rotary Switches

- Common Issues with Rotary Switch 3 Position Components

- How to Replace a Rotary Switch Safely

- Conclusion

- FAQs

What are Rotary Switch 3 Position Components?

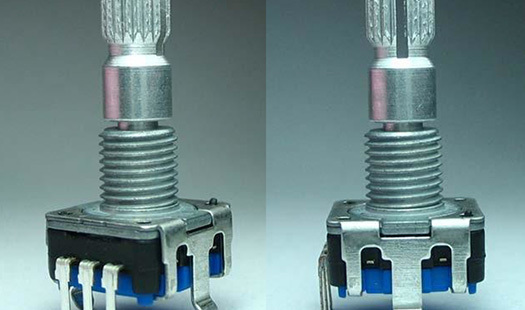

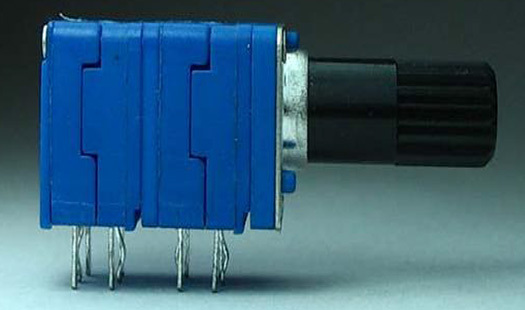

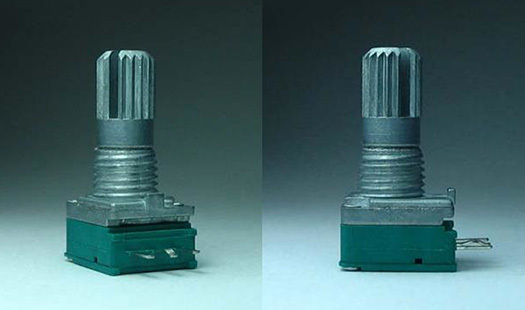

Rotary switch 3 position components are electrical switches that allow users to select between three distinct circuit paths. These components are commonly found in various applications, including audio equipment, industrial machines, and consumer electronics. Their design typically features a knob that can be turned to one of three positions, making them user-friendly and efficient for controlling multiple functions.

How Rotary Switches Work

The functionality of rotary switches lies in their mechanical design. Inside a rotary switch, a movable contact is connected to a series of fixed contacts. When you turn the knob, the movable contact rotates and makes contact with one of the fixed contacts, completing the electrical circuit. This simple yet effective mechanism allows users to easily select different functions or settings, demonstrating the importance of reliable construction in these components.

Factors Affecting the Lifespan of Rotary Switch 3 Position Components

Understanding the lifespan of rotary switches requires examining various factors that can impact their durability and performance. Here are some key elements to consider:

1. Quality of Materials

The materials used in constructing rotary switches significantly affect their lifespan. High-quality metals and plastics are essential for ensuring durability. Components made from inferior materials may wear down quickly, leading to premature failure.

2. Frequency of Use

The more often a rotary switch is used, the more wear and tear it experiences. Frequent operation can accelerate the degradation of internal components, reducing the overall lifespan of the switch.

3. Environmental Conditions

Rotary switches are sensitive to environmental conditions such as humidity, temperature, and exposure to dust or chemicals. For instance, excessive humidity can lead to corrosion, while extreme temperatures can affect the material properties of the switch.

4. Electrical Load

Every rotary switch has a specified electrical load capacity. Exceeding this capacity can cause overheating and damage, leading to a shorter lifespan. It is crucial to match the switch's rating with the application to ensure longevity.

5. Installation Practices

Proper installation is vital for the longevity of rotary switches. Incorrect wiring or inadequate support can create stress on the switch, resulting in mechanical failure or poor performance over time.

Typical Lifespan of Rotary Switch Components

The lifespan of rotary switch 3 position components can vary widely based on the factors discussed above. Generally, high-quality rotary switches can last anywhere from 10,000 to 50,000 cycles or more. However, environmental factors and usage frequency can significantly impact this range. For instance, a rotary switch used in a controlled environment with minimal use may last much longer than one that is frequently operated in harsh conditions.

Best Practices for Maintaining Rotary Switches

To maximize the lifespan of rotary switch 3 position components, implementing regular maintenance practices is essential. Here are some best practices:

1. Regular Inspection

Conduct regular inspections to check for signs of wear, corrosion, or mechanical failure. Early detection can prevent issues from escalating and prolong the switch's lifespan.

2. Cleanliness

Keep the area around the rotary switch clean and free of dust and debris. Dust can accumulate inside the switch, causing mechanical issues and reducing performance.

3. Lubrication

Using the appropriate lubricant can help reduce friction between moving parts. However, it is essential to use lubricants that are compatible with the materials used in the switch to avoid damage.

4. Avoid Overloading

Be mindful of the electrical load on the rotary switch. Ensure that it operates within its rated capacity to prevent overheating and damage.

5. Proper Storage

If rotary switches are not immediately installed, store them in a dry, cool place away from direct sunlight. Proper storage can help maintain their integrity until they are ready for use.

Common Issues with Rotary Switch 3 Position Components

Despite their durability, rotary switches can encounter common issues that affect their performance. Understanding these problems can help users troubleshoot effectively:

1. Mechanical Binding

If a rotary switch becomes difficult to turn, it may be due to mechanical binding. This issue can arise from dirt accumulation or lack of lubrication.

2. Electrical Malfunction

Electrical issues may manifest as intermittent functionality or complete failure. This could result from worn contacts or internal damage.

3. Corrosion

Corrosion can significantly impact the performance of rotary switches, especially those exposed to moisture. Regular inspection and cleaning can help mitigate this issue.

4. Wear and Tear

Over time, the internal components of a rotary switch may wear down due to constant use. Signs of wear may include erratic operation or failure to engage.

How to Replace a Rotary Switch Safely

Replacing a rotary switch can be a straightforward task if done correctly. Follow these steps to ensure a safe and effective replacement:

1. Power Off

Always ensure the power is turned off before attempting any replacement. This step is crucial for safety.

2. Remove the Old Switch

Carefully disconnect the wires from the existing rotary switch, noting their positions for reinstallation. Once disconnected, remove the switch from its mounting.

3. Install the New Switch

Position the new rotary switch in its place and securely mount it. Reconnect the wires according to the original configuration, ensuring a solid connection.

4. Test Functionality

After replacing the switch, restore power and test its functionality. Ensure that all positions engage correctly and that the switch operates smoothly.

Conclusion

Understanding the lifespan of rotary switch 3 position components is essential for anyone involved in electronics. By considering factors like material quality, usage frequency, and environmental conditions, along with implementing best practices for maintenance, users can significantly enhance the longevity and performance of these critical components. By being proactive about inspections and replacements, we can ensure that rotary switches continue to function reliably in various applications, enhancing overall device performance.

FAQs

1. What is the average lifespan of a rotary switch?

The average lifespan of a rotary switch can range from 10,000 to 50,000 cycles, depending on various factors such as quality, usage, and environmental conditions.

2. Can rotary switches be repaired?

In some cases, rotary switches can be repaired, especially if the issue is mechanical. However, it is often more practical to replace a faulty switch.

3. How do I know if my rotary switch is failing?

Signs of a failing rotary switch include difficulty turning the knob, intermittent functionality, and unusual noises during operation.

4. Are there different types of rotary switches?

Yes, there are various types of rotary switches, including single-pole, multi-position, and multi-circuit switches, each designed for specific applications.

5. What should I do if my rotary switch gets wet?

If a rotary switch gets wet, it should be dried thoroughly and inspected for corrosion or damage. If damaged, it may need to be replaced to ensure safety and functionality.

PREVIOUS:

More Information

More Information

RECOMMENDED