The Essential Role of China Potentiometer Knobs in Electronic Components

Jun 11,2025

1. Introduction to Potentiometers and Their Knobs

Potentiometers are critical components in the electronics field, serving as adjustable resistors that enable precise control over voltage, current, and signal levels. The **potentiometer knob** is an essential part of this component, allowing users to manipulate settings easily. This article aims to explore the intricate relationship between potentiometer knobs, their design, manufacturing, and applications, particularly focusing on the contributions of Chinese manufacturers.

2. Significance of Potentiometer Knobs in Electronic Design

The importance of potentiometer knobs extends beyond mere aesthetics. They play a vital role in user experience by providing intuitive control mechanisms for a variety of devices. Whether it is adjusting the volume on a speaker, calibrating a sensor, or tweaking the brightness of a display, these knobs facilitate **user interaction** and enable precise adjustments. The design and functionality of potentiometer knobs directly influence the overall performance and reliability of electronic devices.

2.1 Enhancing User Experience

User experience is paramount in electronic design. A well-designed potentiometer knob offers tactile feedback, allowing users to feel the adjustments they are making. This feedback loop can significantly improve usability, particularly in devices where precision is critical, such as medical equipment and audio devices.

2.2 Impact on Device Performance

The performance of electronic devices is highly dependent on the quality of their components. High-quality potentiometer knobs ensure minimal wear and tear, leading to consistent performance and longevity. As electronic devices become more sophisticated, the demand for precise control mechanisms like potentiometer knobs continues to rise.

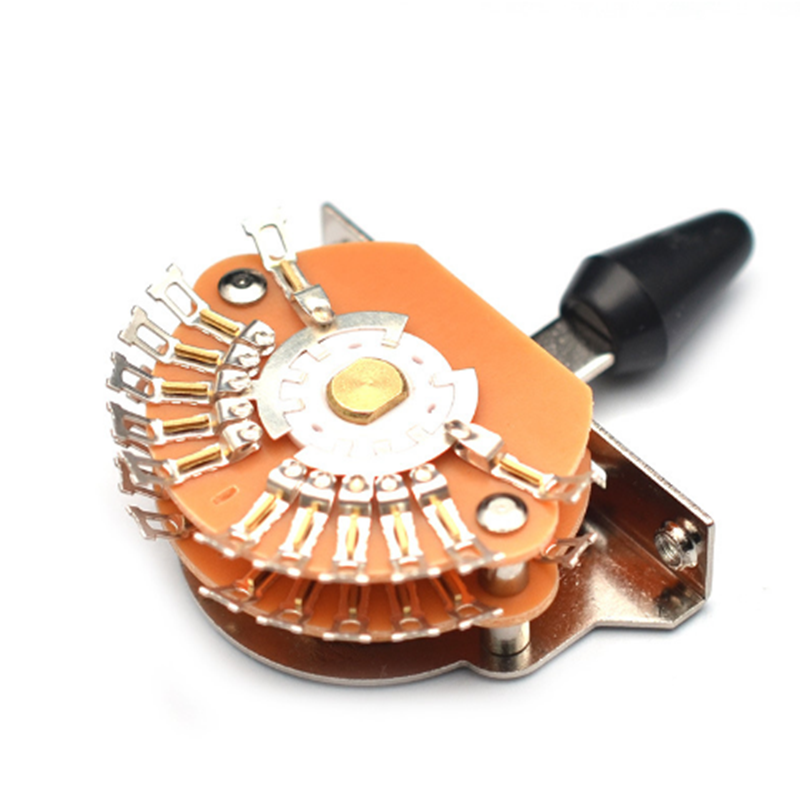

3. Types of Potentiometer Knobs and Their Uses

Understanding the various types of potentiometer knobs available can help manufacturers select the right component for their specific needs. Below are the most common types:

3.1 Standard Knobs

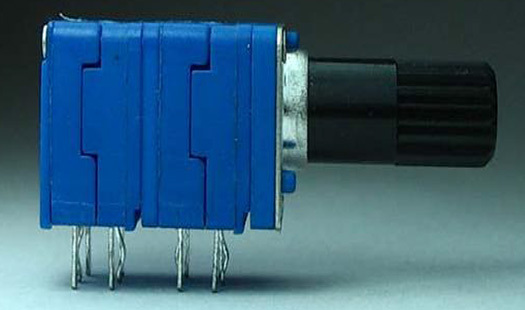

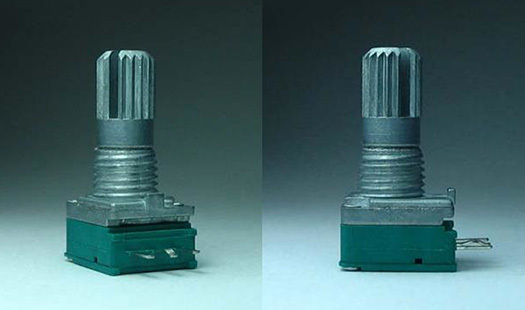

Standard knobs are the most widely used and are typically made of plastic or metal. They come in various shapes and sizes to fit different potentiometer shafts. These knobs are suitable for general applications, including consumer electronics and household appliances.

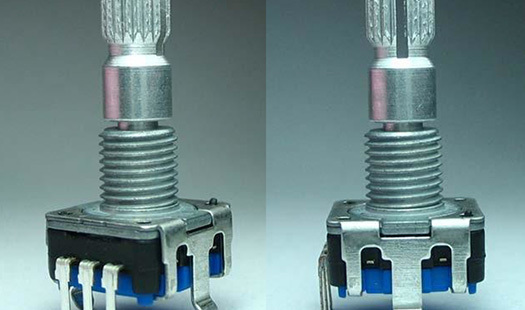

3.2 Knurled Knobs

Knurled knobs feature a textured surface that provides a better grip, making them ideal for applications requiring frequent adjustments. They are commonly found in audio equipment and professional devices where precision is crucial.

3.3 Knobs with LED Indicators

These knobs integrate LED lights that indicate the current setting, enhancing visibility in low-light conditions. They are especially popular in modern audio-visual equipment and smart home devices.

3.4 Custom Knobs

Manufacturers often require custom potentiometer knobs tailored to specific design aesthetics or functional requirements. Custom knobs can be designed to fit unique applications, enhancing brand identity and user interaction.

4. Manufacturing Process of Potentiometer Knobs in China

China has established itself as a leading manufacturer of electronic components, including potentiometer knobs. The manufacturing process typically involves several stages:

4.1 Material Sourcing

The first step in manufacturing potentiometer knobs is sourcing quality materials. Common materials include high-grade plastics and metals, chosen for their durability and resistance to wear and tear.

4.2 Molding and Shaping

Once materials are sourced, the molding process begins. Injection molding is commonly used to create precise shapes and designs for the knobs. This process ensures consistency and uniformity across production batches.

4.3 Finishing and Quality Control

After molding, the knobs undergo finishing processes, which may include painting, texturing, or adding logos. Rigorous quality control checks are implemented to ensure each knob meets industry standards and specifications.

4.4 Packaging and Distribution

Once completed, the potentiometer knobs are packaged and prepared for distribution to clients worldwide. Efficient logistics systems ensure timely delivery, enabling manufacturers to meet market demand.

5. Material Selection for Enhanced Durability and Performance

The choice of material significantly impacts the performance and durability of potentiometer knobs. Manufacturers must consider several factors when selecting materials:

5.1 Plastic vs. Metal

Plastic knobs are lightweight and cost-effective, making them suitable for consumer electronics. However, metal knobs offer superior durability and a premium feel, often preferred in professional applications.

5.2 Resistance to Environmental Factors

Materials must withstand various environmental factors, including temperature fluctuations, humidity, and exposure to chemicals. Selecting materials with suitable properties ensures longevity and reliable performance.

5.3 Aesthetic Considerations

The visual appeal of potentiometer knobs can influence consumer choices. Manufacturers often experiment with colors, textures, and finishes to create attractive designs that resonate with their target audience.

6. Applications of Potentiometer Knobs in Various Industries

Potentiometer knobs find applications across a range of industries, including:

6.1 Consumer Electronics

From televisions to sound systems, potentiometer knobs are integral to enhancing user control over devices, allowing for easy adjustments of settings.

6.2 Automotive Industry

In vehicles, potentiometer knobs are used for various controls, including climate settings and audio systems, providing drivers with intuitive interfaces.

6.4 Industrial Equipment

Industrial machinery utilizes potentiometer knobs for calibrating settings, controlling speed, and adjusting operational parameters, contributing to efficiency and safety.

6.5 Medical Devices

In medical applications, precision is paramount. Potentiometer knobs allow healthcare professionals to make accurate adjustments in devices such as monitoring equipment and surgical tools.

7. Emerging Trends in Potentiometer Knob Design

The design of potentiometer knobs is continually evolving to meet the demands of modern technology:

7.1 Smart Technology Integration

With the rise of smart devices, potentiometer knobs are being integrated with digital interfaces, allowing for both analog and digital control, enhancing user experience.

7.2 Sustainable Materials

As environmental concerns grow, manufacturers are exploring sustainable materials for potentiometer knobs. Biodegradable plastics and recycled metals are gaining traction in manufacturing processes.

7.3 Enhanced Ergonomics

Designers are increasingly focusing on ergonomics, creating knobs that are comfortable to use and easy to manipulate, catering to user needs in various applications.

8. Conclusion

The role of China potentiometer knobs in electronic components is pivotal for achieving precision and enhancing user interaction across various devices. From their manufacturing processes to applications in diverse industries, these knobs contribute significantly to the functionality and reliability of electronic devices. As technology continues to evolve, the design and application of potentiometer knobs will undoubtedly adapt, ensuring that they remain at the forefront of electronic innovation.

More Information

More Information

RECOMMENDED